DW RUPE

“RUPE” is shorthand for “Response to Underwater Pipeline Emergencies,” the name given to the project over 30 years ago by the founding Co-Owners. “DW RUPE is the deepwater equivalent with ROV supported rather than diver-supported equipment.

Current Co-Owners

- Genesis Energy

- Enbridge Offshore Facilities, LLC

- Anadarko US Offshore, LLC

- Woodside Burrup Pty. Ltd.

Project Manager

Stress Engineering Services, Inc., is the contracted project manager for the co-owners. See information about Stress Engineering Services, Inc. at www.stress.com

Purpose

DW RUPE is a co-ownership project designed to procure, store, maintain and deliver project-owned, diver-less 1500 ANSI pipeline repair clamps and spoolpiece connector systems, as well as ancillary equipment such as pipe lifting frames, pipe cutting equipment and weld/FBE removal and end preparation equipment. DW RUPE stores a complete repair system, with connector and clamp sizes from 10 through 24 inches, and other ancillary equipment, appropriately sized to provide emergency response service for participating companies. The DW RUPE pipe connecting and clamping tools are designed according to ASME Section 8 Division II.

Repair Tools

On behalf of the Co-Owners, the DW RUPE Repair System Project Manager, SES, stores and maintains over 12 million USD in ROV-operated repair tools for use in water depths to 10,000 feet. The repair tools consist of:

- Structural Repair Clamps: These are single full encirclement clamps that are intended for use in small pin-hole leak situations or when defect lengths are very short.

- Spoolpiece Repair Systems: These systems are used when a badly damaged section of pipeline is to be removed and replaced by a “spoolpiece”. These systems include end connectors to grip and seal against the cut pipe ends and ball joints to handle misalignment between the cut pipe ends. Part of the repair operation is to assemble a spoolpiece of proper length to match the cut-out section of pipe. This is done on the deck of the repair vessel.

- Pipe Lift Frames and Indexing Frames: These frames are used for lifting the damaged pipeline off the seafloor and aligning it for optimum repair operations.

- Pipe Cutting, End Preparation and FBE/Weld Seam Removal Components. These components are used to cut out a damaged pipeline section (if needed) and to prepare the pipeline repair location for attaching connectors or structural clamps.

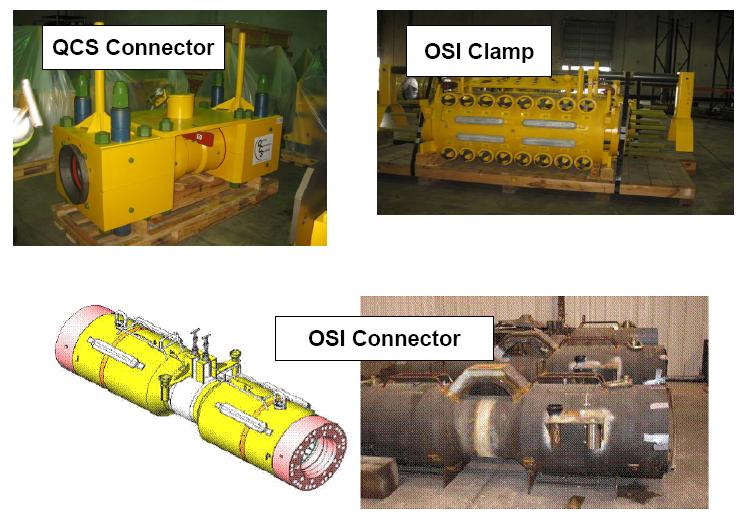

Photographs of Tools & Equipment

Fabrication and SIT Testing

All components of the DW RUPE Repair System have successfully passed both factory-acceptance tests and system integration tests.

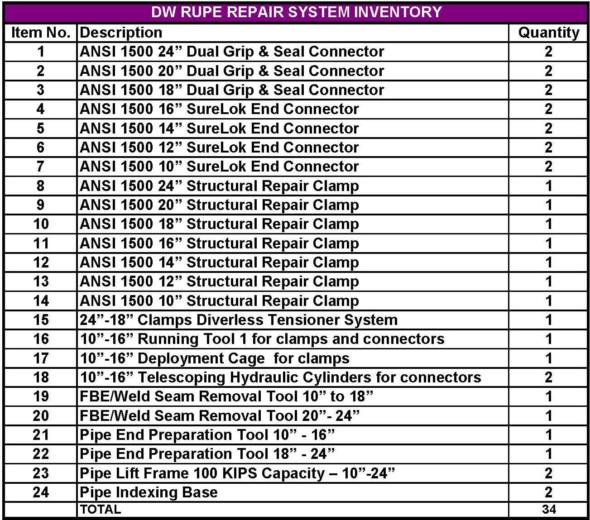

Repair System Component Inventory

The following table summarizes our inventory of repair tools:

DW RUPE Benefits to Co-Owners

When a pipeline repair emergency occurs, the owner has two objectives:

- Minimize environmental damage

- Minimize production downtime

DW RUPE is an effective insurance policy to assist in both objectives. DW RUPE Co-Owners who have dedicated their pipelines to the consortium have the assurance of knowing that a complete repair system – for installing either clamps or spoolpiece systems in the correct size – are warehoused and rapidly deployable for delivery. The other alternative is for each pipeline system owner to purchase in advance and maintain a dedicated set of tools for each individual pipeline size – a much more expensive alternative. DW RUPE, on the other hand, has repair tools in sizes as decided by the Co-Owners.

It is fortunate for the DW RUPE Repair System Co-Owners that clamps and connectors are built for long-term service. It is practical to warehouse tools for decades, with essentially no damage incurred to the tool due to aging, provided that routine inspection and maintenance is kept up to date. Tools have been designed to ASME Section 8 Division 2 Code for decades, and the basic designs have changed very little in decades.

DW RUPE personnel will rapidly mobilize resources to transport to and assemble components of the repair system at a Gulf of Mexico shore location or or other location requested by the affected co-owner.

To Become a DW RUPE Repair System Co-Owner

To discuss becoming a DW RUPE Co-Owner, call 1-281-955-2900 and ask for Melissa Gould or Wendy Davis.

Any local or international pipeline owner can become a Co-Owner of DW RUPE. The requesting company must make formal application through the Project Manager, naming the miles of various pipeline sizes that are desired to be dedicated to DW RUPE. If the request is made as the result of an emergency, there will be additional fees assessed. The Project manager will calculate the asset buy-in fee, and if the company still wishes to join, the Co-Owners will vote on the new member request. A 2/3 majority is needed to permit a new member to join.

The cost of becoming a new co-owner will be determined by summing the fractional ownership in the pipe size-specific tool costs, with the equally-shared costs of the non-size specific components.

Summary of Current Pipeline Dedications

| DW RUPE REPAIR SYSTEM – DEDICATED MILES OF PIPELINE BY SIZE | |||||||

| Size (inches) | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| Co-Owners: | |||||||

| Genesis Energy | 0.00 | 8.90 | 61.02 | 85.49 | 181.26 | 165.82 | 82.88 |

| Enbridge | 0.00 | 38.05 | 0.00 | 52.00 | 0.00 | 25.00 | 0.00 |

| Anadarko | 62.31 | 36.55 | 18.50 | 0.00 | 0.00 | 0.00 | 0.00 |

| Woodside | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 33.991 | 0.00 |

Current Approved Vendor List

The DW RUPE Repair System, as developed, initially consists of components from the following manufacturers:

- Oil States – 18 to 24 inch connectors and structural clamps

- Oil States QCS – 10 to 16 inch connectors and structural clamps

- Custom-built pipe handling frames

- Oceaneering FBE/weld seam removal and pipe end preparation tools

- Other misc. components from various vendors

When it becomes necessary to replace components, the replacements will be decided upon based on bids made using DW RUPE specifications to be developed. It is the DW RUPE intention to competitively bid all replacement components to the system.

2023-02-16